Explosion proof electrical equipment is widely used in hazardous areas of Zone 1 and Zone 2 in explosive gas environments. In order to facilitate users to observe, record, or distinguish the display data, operating status, or basic lighting function inside the device, manufacturing companies often install some transparent parts on the explosion-proof shell. The correct design, installation, and later use and maintenance of related components of the transparent parts directly affect the integrity and reliability of the explosion-proof shell.

The transparent components on the explosion-proof shell mainly include the transparent cover of lighting fixtures, instrument windows, and indicator lampshades. The transparent cover of lighting fixtures comes in the shape of a bell, a long tube, and a flat plate. Instrument windows are mostly flat, and transparent parts should be made of glass or other materials that are resistant to mechanical, thermal, and chemical effects, and can withstand the specified tests. The transparent parts of the lamp can be directly sealed with the outer shell.

The commonly used transparent materials for explosion-proof shells include engineering plastics and glass. This article will explain the commonly used plastic transparent parts and glass transparent parts.

1、 Selection of transparent material

Transparent glass components:

This is currently the most commonly used explosion-proof product transparent component in the market, with stable performance, reliability, high temperature resistance, and good transparency.Glass is resistant to high temperatures and can maintain its transparency under humid conditions for a long time, without the need for separate testing and evaluation of its light aging, heat and cold resistance properties. When selecting transparent glass components, there is no need to consider the risk of static electricity generated during the maintenance process of the glass parts. Based on the inherent characteristics of glass transparent components, they have been widely used in explosion-proof enclosures. Currently, the commonly used material for glass transparent components is tempered glass,Tempered glass has strong impact resistance and thermal stability compared to ordinary glass, and can generally withstand three times the temperature difference of ordinary glass.

Plastic transparent parts:

When using engineering plastics, the mating parts between the engineering plastics and the explosion-proof shell can be glued together to form a bonding interface,Transparent parts made of this type of material should have heat resistance and be able to withstand type tests such as impact resistance and combustion resistance under high and low temperature conditions,If the plastic transparent parts are not glued to the explosion-proof shell, then for explosion-proof shells with a cavity volume greater than 50 cubic centimeters, in addition to being able to withstand other types of tests, according to the requirements of GB3836.2-2010, flame erosion tests need to be added to the transparent parts, which makes the selection of plastic transparent parts more stringent.

In addition, due to the inherent characteristics of plastics, long-term exposure to ultraviolet light environments can lead to agingWe need to conduct a photo aging experiment,Such equipment should have anti light measures after installation.

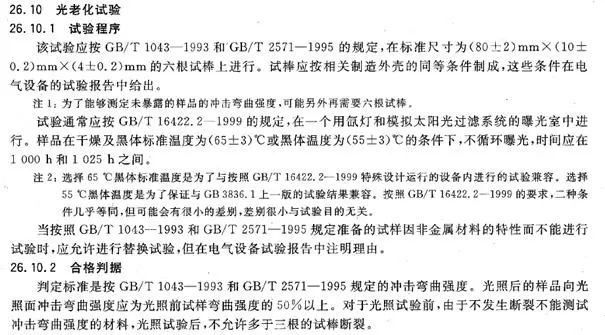

Light aging test:

Six samples made according to the standard are exposed in a room simulating a solar system without cyclic exposure for 1000h-1025h. The bending strength of the samples after illumination is more than 50% of that before illumination, and no more than three test rods are allowed to break.

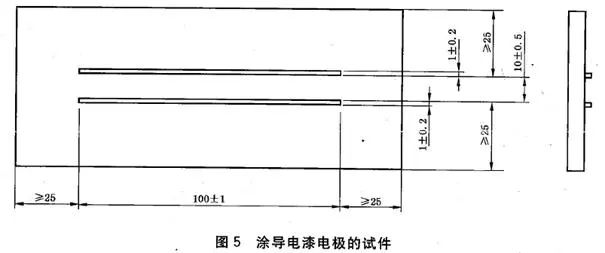

Surface resistance test:

The test pieces provided according to the standard requirements should be wiped clean with distilled water, cleaned with isopropyl ethanol, and then cleaned with distilled water before drying. They should be placed in the environment required by the standard for 24 hours. Apply a voltage of (500 ± 10) V between the two poles of the test piece for (65 ± 5) seconds. The measured surface insulation resistance is ≤ 1G Ω.

remarks:

1) Surface coating with anti-static paint: This method is not conducive to long-term use of the product. As the anti-static paint may peel off over time during actual use, it is recommended to apply it again every 3 to 6 months.

2) Fixed products can be equipped with a warning on the shell: potential electrostatic charge hazard. Refer to the user manual, which states that when wiping transparent parts, please use a damp cloth.

(3) Key design points for plastic transparent parts:

1) Transmittance: When processing, adding 0.3% or 0.4% glitter powder to the material can achieve a light efficiency of 70% -80%.

2) Injection molding machine: Choose 180-250 tons, and the shrinkage phenomenon will not be very obvious.

3) Excessive hydrostatic pressure: Strengthen the back with reinforcing ribs, with a thickness not exceeding 0.6 of the wall thickness (severe shrinkage after exceeding). Vertical reinforcement bars should be added below the transparent component and fixed with at least 8 screws to withstand a hydrostatic pressure of 1.5MPa.

4) Fasteners: Q235 coated with blue zinc reduces the cost by half compared to using 304 material.

|

||||||

|

||||||